Understanding the Needlework Digitizing Process: Your Ultimate Guide

Needlework digitizing is a thorough craft that requires accuracy and proficiency to translate intricate layouts right into digital layouts for equipment embroidery. As artisans start this journey to master the embroidery digitizing process, a detailed understanding of the basics sets the structure for quality. Beyond the primary understanding exists a world of sophisticated software program, specialized tools, and nuanced techniques waiting to be explored. By diving into the subtleties of digitizing, one can open a world of creative opportunities and boost their embroidery projects to new elevations.

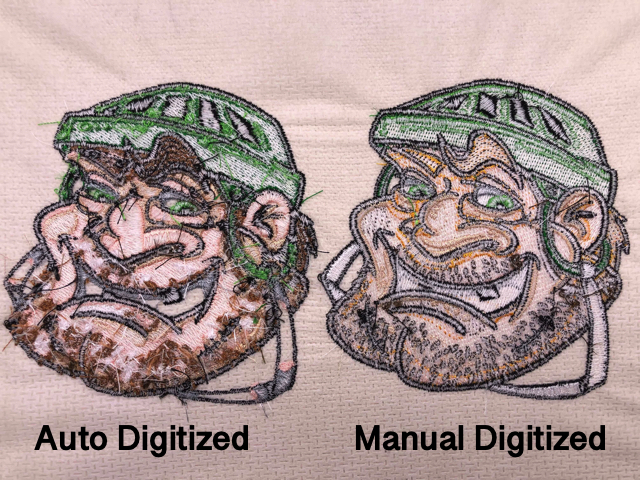

Understanding Embroidery Digitizing Basics

Needlework digitizing basics create the structure upon which detailed layouts are converted right into machine-readable layouts for specific stitching. This preliminary step in the needlework digitizing process is essential for making certain that the final stitched product is a loyal depiction of the initial design. Understanding embroidery digitizing fundamentals entails grasping vital concepts such as stitch kinds, stitch instructions, thickness, rug, and draw settlement.

Stitch kinds play an essential function in establishing the visual and textural end result of the embroidered style. By choosing the proper stitch kind, whether it be satin, fill, or running stitch, digitizers can accomplish the preferred effect and enhance the overall top quality of the embroidery. In addition, stitch direction influences the flow and dimension of the design, while thickness identifies the spacing and coverage of the stitches.

Furthermore, padding sewing provides stability to the style by safeguarding the fabric and preventing distortion during the embroidery process. Draw compensation is an additional vital factor to consider to neutralize the natural tendency of fabric to contract when sewn. Grasping these embroidery digitizing essentials is essential for creating professional-quality embroidered products.

Picking the Right Digitizing Software Application

Selecting the proper digitizing software is a vital decision that dramatically affects the effectiveness and high quality of the needlework digitizing process. Digitizing for Embroidery. When picking the right digitizing software application, it is vital to think about factors such as the intricacy of designs you intend to create, the user-friendliness of the software program, the level of customer assistance used, and the compatibility with your embroidery equipment

There are numerous digitizing software application options offered out there, ranging from fundamental programs for newbies to advanced software program for professional digitizers. Some popular selections include Wilcom EmbroideryStudio, Hatch Embroidery Software Application, and PulseID. These software application plans supply a vast array of devices and attributes to assist you produce elaborate layouts effortlessly.

Before deciding, it is a good idea to discover the different software program choices via cost-free trials or demos to identify which one ideal fits your needs. In addition, checking out testimonials and seeking referrals from experienced digitizers can supply valuable understandings right into the toughness and weak points of each software (Digitizing for Embroidery). By thoroughly evaluating your needs and contrasting the functions of various digitizing software, you can make an informed selection that improves your embroidery digitizing operations

Digitizing Devices and Methods

Optimizing Layout Settings for Needlework

Grasping the details of layout settings is basic in achieving optimal outcomes in the needlework digitizing process, building upon the foundation laid by understanding digitizing tools and methods. When optimizing layout setups Visit Website for needlework, it is vital to consider aspects such as stitch kind, thickness, rug, pull payment, and enrollment. Registration setups line up various elements of the design accurately, keeping general design stability.

Troubleshooting Common Digitizing Issues

When experiencing typical digitizing concerns throughout the embroidery procedure, it is necessary to comprehend the origin creates and implement reliable options without delay. One common issue is stitch density issues, where stitches may be also dense, triggering the fabric to pucker, or also thin, leading to gaps in the style. Readjusting the stitch density settings in the digitizing software can help fix this issue.

Another regular difficulty is string breaks during the needlework process. This can occur because of various factors such as incorrect tension setups, dull needles, or utilizing low-quality thread. Guaranteeing appropriate upkeep of the embroidery equipment, including regular needle changes and stress adjustments, can minimize the event of string breaks.

Moreover, style registration errors can cause misaligned aspects within the embroidery layout. Examining the layout placement in the digitizing software and making required adjustments before stitching can help in avoiding this problem. By dealing with these usual digitizing issues without delay and properly, you can make certain a smoother needlework process and top notch finished products.

Verdict

In verdict, mastering the needlework digitizing procedure needs a strong understanding of my website the essentials, the right option of software application, and knowledge of tools and methods. Maximizing design settings and fixing usual digitizing issues are essential actions in making certain high-grade needlework results. By following these actions faithfully, one can accomplish precision and performance in the digitizing process.